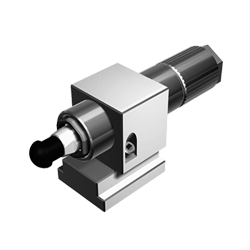

XL

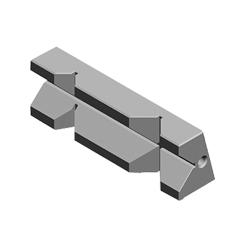

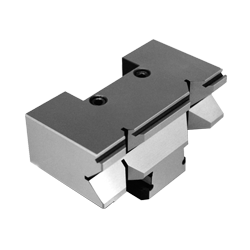

Vises with the extra large base dimension, much longer than STD vises.

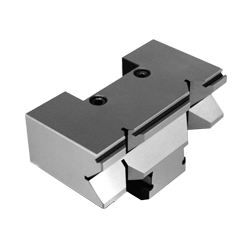

Space on the Machine table sometimes is tight, XL vises enable to have 2 vises in one because they can easily and quickly change from large opening single station vise into a double clamping station.

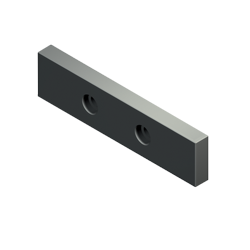

With the double XL vise a higher number of work-pieces can be machined in the same work cycle exploiting as much as possible the machine table length, this means to increase the productivity of the work cycle and of the machine itself because:

- Reduction of total number of loading and unloading with consequence save of dead times/interruptions when the machine is not working;

- Reduction (50%) of total tool changing time;

- Lower moving time from a series of workpieces to another one of different types;

- Lower machine wear;

- More time the operator can walk away to do other work because of longer total cycle times.

In conclusion all this means to increase the machine productivity because of the reduced dead times/interruptions and consequently faster payback period of machines and fixtures too.

Single XL vise allows to clamp workpieces and plates of unusual dimensions and plates (with the right jaws). The very wide range of widths and lenghts of bases guarantees the satisfaction of the widest variety of works and a big rigidity of the fixture too.