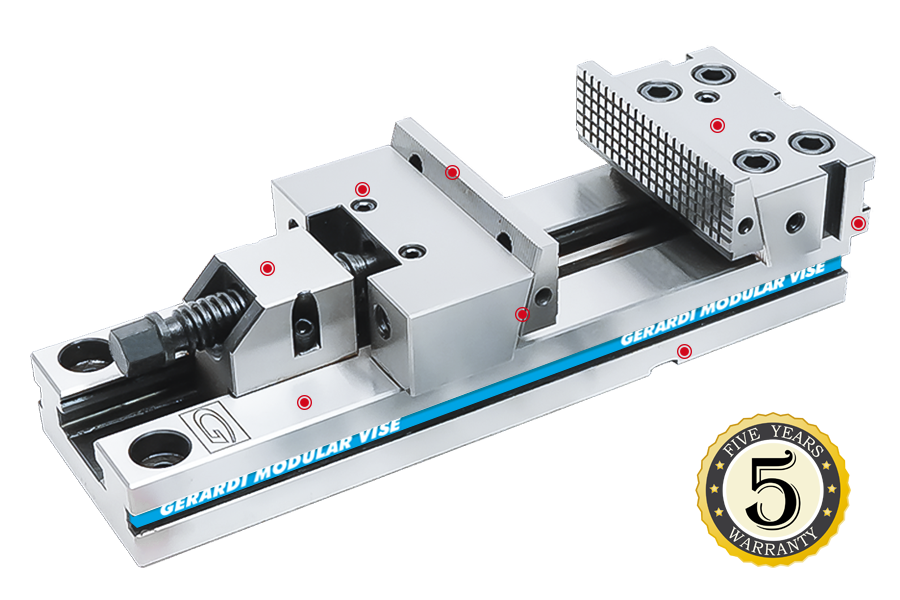

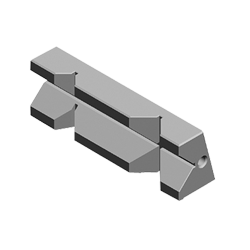

NO WEAR

Thanks to the manufacturing with only the most suitable materials and to the structure of the vise components.

High alloyed quality resistance steel, case hardened HRC 60 ±2, is used in manufacturing all the Gerardi vises and accessories in order to give maximum rigidity, high performances and no wear. As evidence we give 5 YEARS WARRANTY on all the vises and mechanical components.

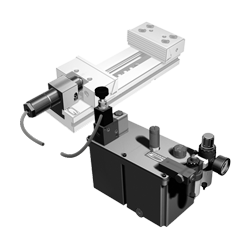

MODULARITY

All vises and accessories are modular and components of all our vises will interchange with perfect alignment to provide different workholding solutions.

With this basic principle the only difference between fixtures with the same width of clamping is the base (whose length determines the maximum opening of the vise), while the rest of components have same dimensions. Through the simple addition or substitution of some components You can change the type of clamping as Your needs require using the same fixture purchased before (single clamping, swivel base, double, vertical, smooth or round or flat or rough workpieces, manual, hydraulic or pneumatic).

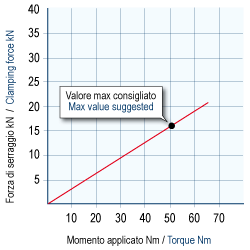

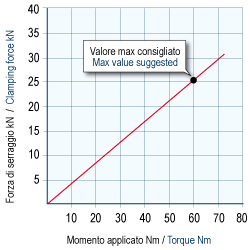

QUICK CLAMPING

Thanks to the clamping device sliding in the vise base slide (compact rack type) till the proximity of the workpiece. The clamping is completed with the main screw. Besides the manual mechanic system, 4 further interchangeable and independent clamping systems are available:

- Hydraulic

- Pneumatic

- Manual hydraulic

- Electrical hydraulic

The change needs only few seconds.

VERSATILITY

Pull-down jaw plates interchangeable by hand and vertical gang operations possibility.

HIGHEST ACCURACIES +/-0,02mm

Every sliding and coupling surface is ground. Centesimal tollerances are guaranteed by checking cycles with CNC measuring machine. The perfect alignment with the machine axis is given by longitudinal and cross keyways (16H7) or positioning holes (Ø16 mm F7), upon specific request, on the vise base. Of course this allows minimum of set up times and gang operations.

BETTER PULL DOWN ACTION

Increased and better pull down straight action and better protection from chips.

GREAT SAVINGS IN VISE RESETTING TIMES

Greatest time savings in vise configuration resetting times thanks to the manual interchangeable quick jaw plate.

VERTICAL GANG OPERATION

Vertical built-in possibility for back to back assembly of 2 vises in order to create a more rigid vertical system on grid or t-slot pallets.