Angle Heads Classic Line

Integral angle heads

The new Classic line of Gerardi angle heads has been designed from a technical base derived from 40 years experience of solving thousands of production problems, finding optimum solutions and always guaranteeing the highest product quality. More than 90 standard angle head types are now offered, designed, built and distributed in more than 50 countries the world over by Gerardi S.p.A., and available with a range of options to complete their application and performance potentials.

The Compact design, along with mentioned specifications, allows: highest performances, high speeds, long tools life.

Identify your Angle Head with our worksheet

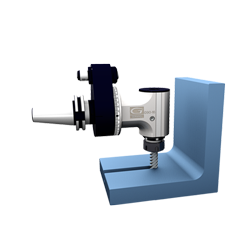

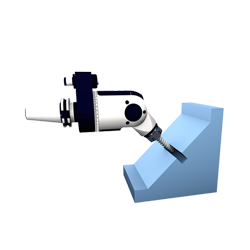

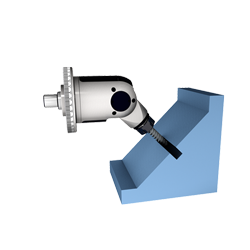

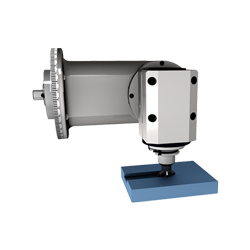

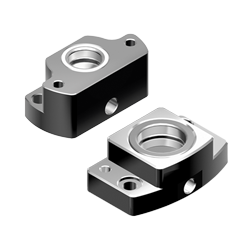

ATC series

This range of heads is designed to be used on machining centres and can be automatically tranferred from the tool magazine to the machine spindle and back.

A major feature of the ATC serie is the main input shaft which is integral with the drive taper to ensure maximum rigidity.

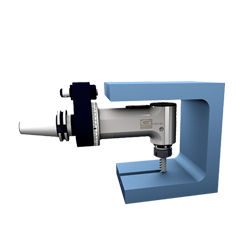

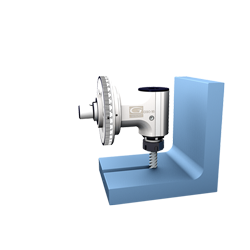

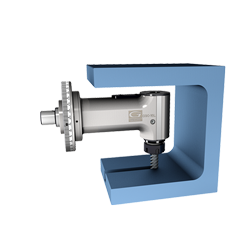

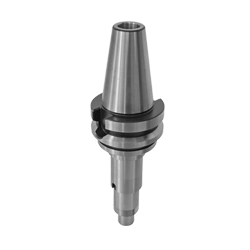

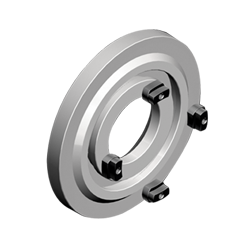

MTC series

This is a range of heads for traditional machine tools with flange attachment.

The modular system makes it possible to extend the lenght of the body by additing a spacer.